The 3 Main Purposes of a Dock Leveler

The warehouse and storage industry is a significant industry in the United States. And while there are many facets to this growing industry, it’s good to know and understand some of the finer workings.

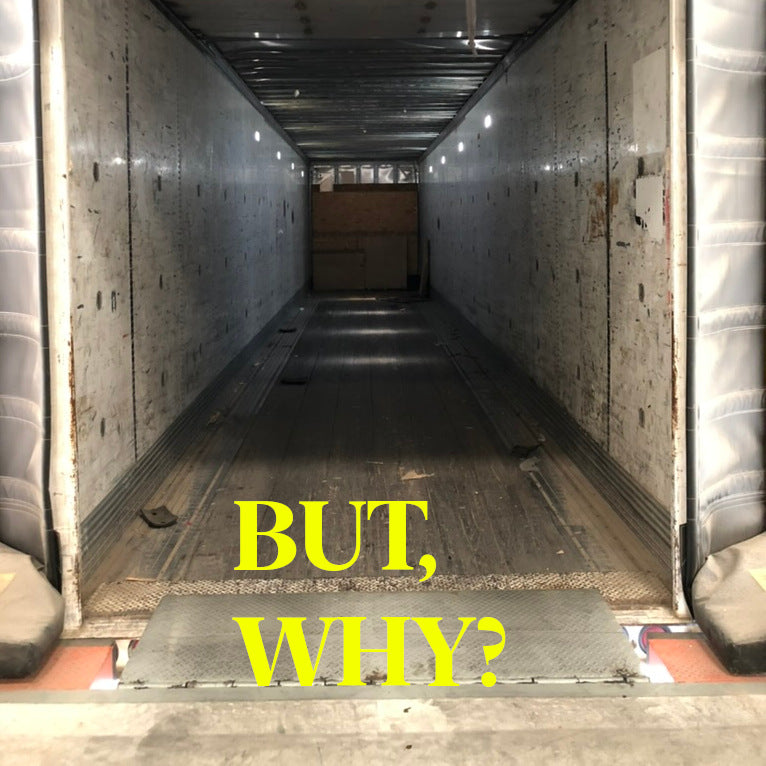

For example, a loading dock is not only the bridge connecting the gap between the transporting vehicle and the warehouse, it also could be said it connects the two industries, as well. It’s a path that needs to be able to carry heavy traffic both during loading and unloading, while also providing safety and protection to those who load the merchandise; a place that connects warehouses and storage and transportation between the two.

Knowing the use of loading docks is vital to understanding the purpose.

The purpose of a dock leveler is to link the loading dock and the trailer, allowing ease of unloading and loading products. It is a pivotal piece of machinery that can either raise or lower to align a smooth transition between the warehouse loading dock and the delivery vehicle.

Using the right type of dock leveler is paramount to safeguarding both the operator and the operation of unloading and loading. Able to withstand the weight, shocks, and bumps of moving merchandise, loading docks are vital for an easy transition.

There are several different types of loading docks, and each type has its own advantages.

The air powered dock leveler is a popular choice, especially in warehouses, due to its economic benefits. A pneumatic bag system raises and lowers the air powered dock leveler, which requires an electrical power source.

As air powered dock levelers have limited moving components, it typically makes for a lower cost option that is easy to repair and maintain.

A hydraulic dock leveler is the most versatile type of dock leveler and is the best option for high traffic areas. Not only is the hydraulic dock leveler typically more resilient than other types, but it is also simple to use with only a push button.

Hydraulic dock levelers also typically require fewer maintenance and service calls during their use due to their durable structure.

Lastly is a mechanical dock leveler. Ironically, it is the cheapest type of dock leveler to purchase and is also the most expensive to maintain.

The mechanical dock leveler doesn’t require electricity, therefore allowing it to be placed anywhere, and simply use a spring to raise and lower. However, to operate the raising and lowering motion, one must use their own body weight. This can be accomplished either by pull string or spring.

Most types of dock levelers have many different features to meet different needs. Some may be installed vertically to multi-function as both dock leveler and barrier. This is mostly used when the dock is leading outside in locations of fluctuating weather.

Some dock levelers can even feature peak load control by enhancing the contact area between the trailer and the dock, such as with the teledock.

No matter the need, there are sure to be features or even attachments that will accomplish the desired result.

Owner, Parts Brite

My background is in Electrical and Software Engineering, but since I started PartsBrite.com in 2016, I've focused on everything related to docks.

My team and I are here to help those looking to repair or replace their dock levelers, bumpers, door, and door lights.

1-855-PartsBrite | partsbrite.com | paul@partsbrite.com

Leave a comment