The 3 Main Differences Between a Dock Plate and a Dock Leveler: A Comprehensive Guide

Understanding the Difference Between a Dock Plate and a Dock Leveler - A Comprehensive Guide

Understanding the benefits and differences between dock plates, dock levelers, and dock boards is critical to choosing the right equipment for loading docks. Our guide outlines all these elements to assist you with making an informed decision that will optimize your operations and maintain safety at your facility.

Short Summary

-

Dock plates and dock levelers offer varying levels of mobility and load capacity, with the latter being more suitable for heavier loads.

-

Maintenance is essential for ensuring safe operation & prolonging the longevity of your dock plate or dock leveler. Safety precautions should be taken in loading dock operations.

Dock Plate Basics

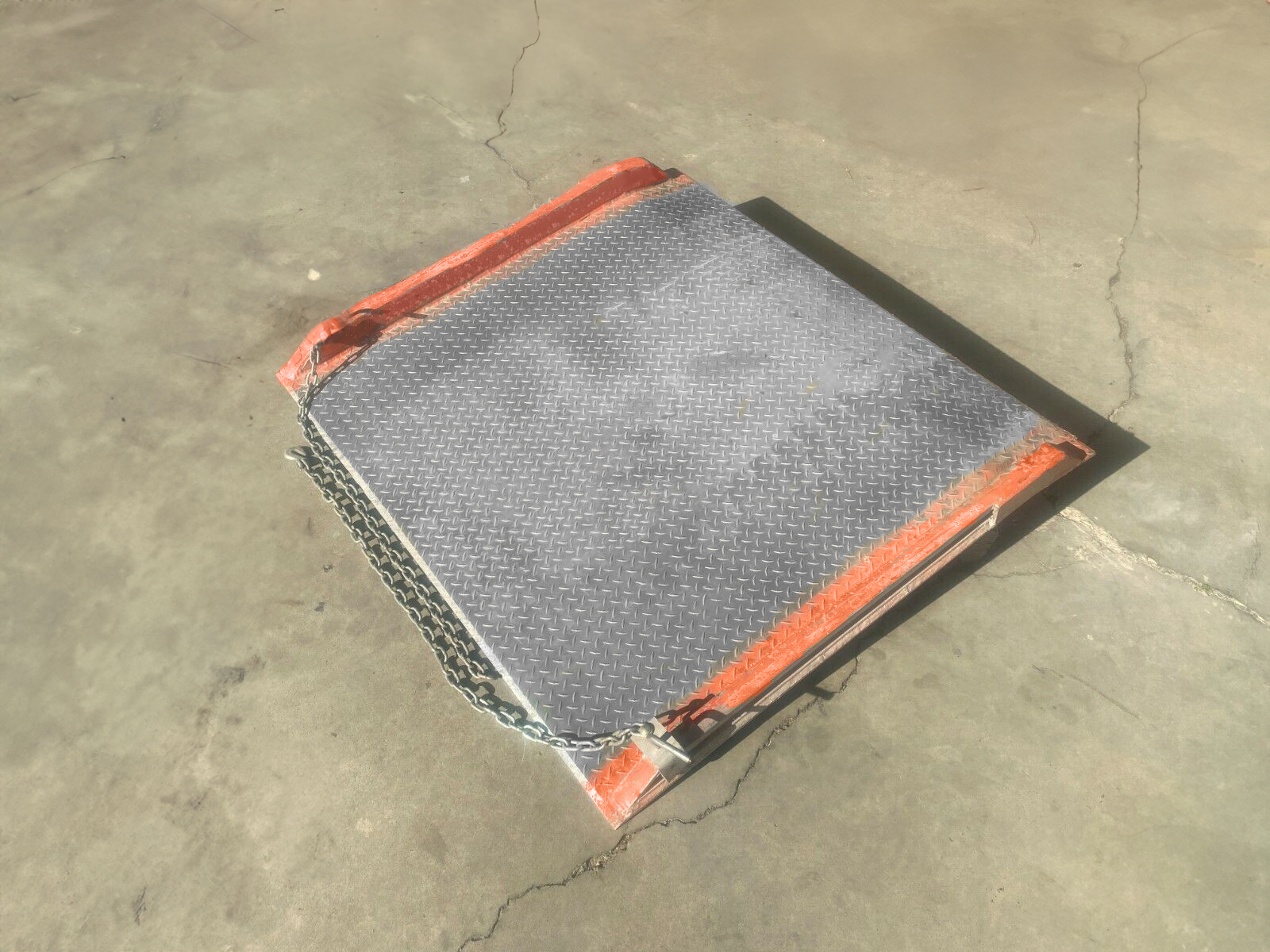

A dock plate is an excellent option for light-use loading dock scenarios. Dock plates are flat metal plates that bridge the gap between the dock and the truck. Dock plates are ideal for use when the height difference between the dock and the truck is minimal, usually less than 5 inches. Dock plates are manufactured with a lightweight aluminum construction to ensure ease of movement. Dock plates are the most portable option.

Sometimes a dock plate will have a colored safety border to provide greater visibility. Regular inspections should be done on all Dock Plates - checking both wear and tear as well as those aforementioned warning stripes – to ensure that only fully-functional units remain in operation at your loading docks. They will run you roughly between $400-$1100 dollars.

Key Features of Dock Plates

Dock plates are an ideal way to provide a bridge between the loading dock and the trailer when handling lighter loads, including hand trucks, pallet jacks, or foot traffic in the loading dock bay. Most dock plates are made out of aluminum because it is lightweight yet strong enough for these kinds of tasks. That is in contrast to the steel used in the construction of dock levelers of both pit and edge of dock style. Dock plates are portable and can be easily moved around the loading dock by a single person.

Dock Leveler Fundamentals

Loading dock levelers are the ideal choice for dealing with heavy loads and the forklift (also called fork truck) needed to move them from the truck. These permanent fixtures provide a smooth transition from the loading dock to the transport vehicle while ensuring the load's safety. Unlike docks plates, which tend not to be suitable for lighter duties, dock levelers have a back hinge and an extension lip that bridge the gap between the dock and the trailer bed and enable uninterrupted loading and unloading.

Types of Dock Levelers

Dock levelers come in three varieties of technology used to raising and lowering the dock leveler.

Hydraulic leveler

Hydraulic dock levelers are operated by an electric pump when the button or remote is pressed to both raise and lower the lip platform. They are ideal for use with powered equipment such as forklifts and are designed to handle loads of up to 100,000 pounds.

Mechanical dock leveler

Mechanical dock levelers require a chain-pulling process to manually lift or release their platform - making them more cost-effective yet less convenient than hydraulic options. Mechanical dock levelers use a spring mechanism to raise and lower the deck and are suitable for handling loads of up to 50,000 pounds.

Pneumatic (often called air-powered) dock leveler

Air-Powered dock levelers are a nice compromise between a hydraulic dock leveler and a mechanical dock leveler. They require power to inflate the air-bag used to lift them just like the hydraulic dock leveler requires power for the hydraulic pump. Air-powered dock levelers have about the same capacity as mechanical dock levelers.

Two main styles come in all three varieties:

Pit Levelers

These are often just called dock levelers as they are the more common of the two.

They are large pieces of equipment installed inside a pit in the concrete of the loading dock.

A dock leveler has a standard operating range of 12” above and 12” below the dock. If you are looking for a leveler to handle heavy loads and heavy equipment, the pit levelers are the best dock leveler for the job. Remember when we are looking at the capacity of a dock leveler you need to consider the combined weight of the forklift and its load.

Edge of Dock (EOD) Levelers

The Edge of Dock (EOD) Levelers are attached to the dock face (or edge), hence it's name. An Edge of Dock leveler has an operating range of 5” above and 5” below the dock. Edge of Dock levelers can have a capacity of as high as 35k pounds. They are a much cheaper alternative to pit levelers if the limitations are within your scope of work.

Comparing Dock Plates and Dock Levelers

Dock plates and dock levelers are both designed for the secure transitioning of goods. They both bridge the uneven gap between the dock and the truck as well as handle the height difference.

The primary difference is that while dock levelers have been built as a permanent structure to accommodate heavier loads, their counterparts - dock plates - are portable and suitable only for lighter loads. A dock leveler can handle greater load capacities due to its longer length, up to 12 feet in some cases, along with 6-foot or greater widths compared with the 3-5 feet width of dock plates. We would be remise if we didn't consider cost. Dock plates are MUCH cheaper than a pit leveler even if you don't include the installstalation.

Choosing the Right Loading Dock Equipment

When it comes to selecting the appropriate loading dock equipment, there are several important factors that need consideration. These include considering what type of vehicles will be utilized for loading and unloading, as well as how much weight/volume is being handled in each instance. Also, take into account the frequency at which these activities occur and if necessary, the maximum lifting capacity provided by any forklift on site.

By assessing all your needs carefully then evaluating available dock plates or dock levelers you can make an informed choice that meets requirements perfectly while ensuring operational safety with lasting results. Dock plates provide a solution when dealing with lighter loads carried via non-powered items, while more robust solutions such as specialized leveling systems become better suited when heavier moving components powered by lift trucks must be managed instead.

Dock Boards: A Third Option

For those needing a higher-strength solution than dock plates but not something permanently attached, the use of dock boards provides an extra option. Dock boards are constructed using steel instead of aluminum used in dock plates. They have steel curbs as a physical barrier and chains to offer increased security for heavy items such as forklifts. These dock boards come equipped to handle weighty loads not suited for just the plate alone. Their specialized safety features help ward off any mishaps from happening on loading docks by stopping run-offs that may occur using plates.

When to Use Dock Boards

Suppose you need to move heavier loads that require heavy-duty machinery, such as forklifts but cannot permanently install a dock pit leveler or attach an edge of dock leveler (EOD) to the dock face. In that case, a dock board is the ideal solution.

Dock boards provide a secure platform for heavy machinery. They have steel curbs measuring 6-8 inches wide to enhance their safety features and should be at least 60 inches wide for optimal support. Dock boards come into play when regular dock plates are not able to cope due to their size or weight limits but don't require anything permanent like an actual dock leveler. The great thing about it is that it bridges this gap between easily movable docks and immovable dock levelers.

Maintenance and Longevity

Taking proper care of loading dock equipment is crucial to guaranteeing its safe and efficient use. To ensure this, it is essential to undertake regular maintenance activities like cleaning the pit area, inspecting lip-out mechanisms, lubricating parts, adjusting the hold-down box, as well as checking weather seals and bumpers on the dockside. It's also wise to create a schedule for inspection & services that conform with manufacturer guidelines & OSHA standards to make sure your dock plates & dock levelers are functioning at their best capability for years down the line, avoiding any unnecessary replacements or repairs.

Safety Considerations

Proper installation and use of dock plates, dock boards, and dock levelers are essential for ensuring safety in loading docks. Workers must wear appropriate protective equipment to guard against collisions or backovers while utilizing locking devices on trucks as recommended by OSHA regulations regarding hazard prevention. Safety should be prioritized at all times so that the working environment stays productive and accidents are kept to a minimum. Following guidelines set out by OSHA with regard to barriers for protection can minimize risks associated with loading dock operations.

Summary

By understanding the advantages each dock plate, leveler, and board provides in load capacity and types of equipment utilized, you can make an educated decision regarding your loading dock needs. This allows for maximum safety as well as efficiency throughout all operations taking place in the loading dock area. When considering factors such as weight limits, vehicle frequency use, and safety protocols, it is important to find solutions that are suitable for your business – something achievable by investigating available options within this type of specialized equipment suite.

Frequently Asked Questions

What is the difference between a dock board and a dock plate?

Dock plates and boards are both intended to fill the gap between a truck or loading dock. The main difference is in their weight capacity: while dock plates, which are lightweight, should be used for light wheeled traffic only. Heavier machinery such as forklifts requires using dock boards instead. Both provide an essential service of connecting trucks to docks when loading or unloading items.

What are the disadvantages of dock levelers?

Dock levelers tend to be more complex and immovable. Hydraulic levelers, the highest capacity levelers, are pricey and require power at the dock. Sometimes you lack the space or funds needed for installation. You also may be working in a facility where you are unable to modify the building.

What is a leveler on a dock?

A dock leveler is a necessary piece of equipment for any loading dock, making sure that goods can be transported safely between the vehicle and the structure itself. It serves as an access bridge so they are able to transfer merchandise efficiently without disturbance.

This type of machinery has adjustable features which allow it to raise or lower according to how high the truck may be positioned. This way, cargo can move from one area into another smoothly and with minimal risks involved. The placement of a dock leveler in your loading facility also ensures that all operations will stay secure while taking place at their designated height levels accordingly.

Owner, Parts Brite

My background is in Electrical and Software Engineering, but since I started PartsBrite.com in 2016, I've focused on everything related to docks.

My team and I are here to help those looking to repair or replace their dock levelers, bumpers, door, and door lights.

1-855-PartsBrite | partsbrite.com | paul@partsbrite.com

Leave a comment